OZONE APPLICATIONS

Due to the tightening of environmental regulations throughout the world, the ozone industry is fast growing and as such new applications for ozone technology are being regularly implemented. Ozone technology has many advantages which have been reliably implemented in water treatments, such as:

- Ozone for Drinking Water

- Ozone for Fruit Cleanning

- Ozone for Swimming Pool

- Ozone for Waster Water

- Ozone for Agriculture Water

- Ozone for Aquaculture Water

Ozone for Drinking Water

Municipal water companies have used ozone technology to treat large quantities of water for many years because of its effectiveness in purifying and conditioning water. Because ozone can be added at the point of water treatment and naturally reverts back to oxygen, it can keep water sanitized throughout a facility.

Water charged with ozone also is suitable for rinsing and cleaning bottles and disinfecting production equipment. This reduces the potential for bacterial growth in unchlorinated water found within the distribution system. It also reduces the amount of clean-in-place (CIP) required to keep the operation disinfected. Many plants have started incorporating an ozonated cap and bottle rinsing system.

Because ozone is so reactive and is a powerful biocide, it is used as the most powerful oxidizing agent permitted to be used on human drinking water. It is more than 50% stronger than simple chlorine treatment, and it works more than three times as fast. This is due to the incredibly damaging effect ozone has on biological life. It weakens the cells of living tissue and causes immediate cell death.

Ozone for Fruit Cleanning

Ozone is a most efficient Natural Broad-Spectrum Microbiological control substance and very reactive Disinfecting agent. In case the vegetables are washed with strong Ozonated water, not only the microbial load on to the surface get reduced or the Ozonated water destroys any Bacteria, Viruses, Cysts and Pathogens on the surface of food items washed with this water, in a very short duration.

The pesticides (which are long chain organic components) gets oxidized to short chain components and finally into harmless elements. To conclude, the Ozonated water or the strong disinfected water used for washing of vegetables and fruits will make them fresh, longer shelf life and organically harmless.

Today use of Ozonated water is considered by most to be the best available and advanced technology for washing fruits and vegetables, CIP and many other applications and a much better alternative than using chemicals.

Ozone for Swimming Pool

Ozone (O3) is a very effective disinfection agent and can be used in swimming pools to replace chlorine and bromine containing disinfection chemicals. The advantage of the use of ozone compared to the other swimming pool treatment agents is the fact that the swimming environment will increase dramatically.

The use of ozone prevents the formation of chlorine or bromine containing byproducts, like chloramines and trihalomethanes. Ozone will even breakdown already formed unwanted chlorinated byproducts. This will reduce problems with red eyes and respiration problems. Ozone will give a sparklier and clearer bathing water. The use of ozone has also the advantage for the swimming pool operator that less fresh water replacement is necessary, which has a big effect on the heating cost.

Ozone is besides an effective disinfection agent also a coaggulation agent, which will increase the performance of the sand- and active carbon filter.

In these norms amongst others a temperature dependent ozone dose is used. For swimming pools with a water temperature of 28°C or 33 – 35°C an ozone dosage of respectively 0.8 and 1.2 gram per m3 is used.

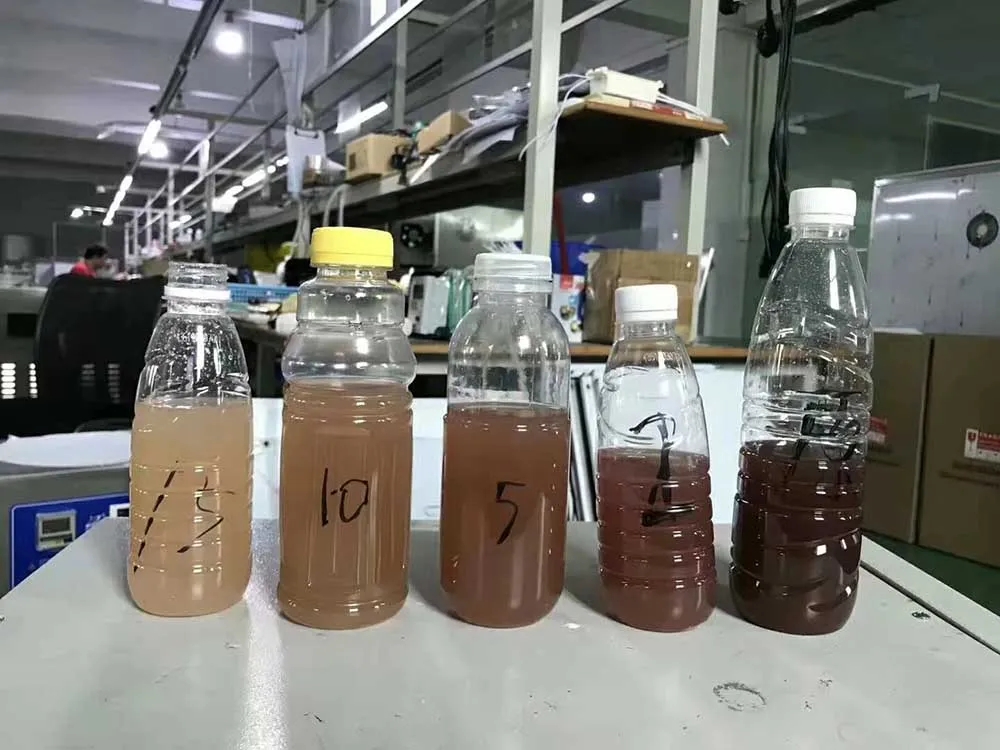

Ozone for Waste Water

Ozone is added to wastewater during the treatment process, removing germs and organic compounds. In effect, the wastewater is being filtered by the O3 chemical, hence the name ozone filtration.

Ozone, if handled correctly, can be a highly beneficial form of wastewater treatment. However, plant managers need to budget carefully to make sure that enough ozone is produced in order to do the job correctly. There may also need to be pre-treatment on the wastewater to get the best out of the process.

Provided that a facility can handle the relative complexity of the process, and bear the cost of operation, ozone filtration is a very viable option.

Ozone for Agriculture Water

Disinfection in agriculture moves towards a reduction in the consumption of synthetic chemicals. With Qlozone you can alternatively apply ozone without affecting the volume and quality of food production. In addition to the pathogens present in the soil, water also poses high risks to crops.

Using ozone will allow the elimination of all pathogens present in the water.

The treatment of water with ozone makes it possible to have no consumption of reagents, as it only uses the oxygen present in the air.

With O3Waves, ozone is dissolved in water for use in irrigation. The ozone present in the water is able to decontaminate soils overloaded with chemical residues from the use of fertilizers and phytosanitary products.

The ozone present in the water acts at the level of the rhizosphere, restoring the natural physicochemical characteristics of the soil, creating more spongy and oxygenated soils, leading to a better absorption of nutrients by the plant roots.

Ozone for Aquaculture Water

Recirculating Aquaculture Systems (RAS) provide potential advantages over pond or cage-based forms of aquaculture. These include flexibility in site selection, reduced water usage, lower effluent volumes, better environmental control, and higher intensity of production. However, as stock densities and levels of water re-use increase, wastes accumulate rapidly and environmental control becomes more difficult. Sophisticated systems capable of removing both particulate and dissolved organic wastes become necessary.

Conventional means of solids removal, such as microscreen filters and sedimentation tanks address the removal of coarse settleable and filterable solids, but not the removal of fine colloidal solids. Similarly, bacterial nitrification in biofilters removes dissolved ammonia and nitrite, but not other dissolved wastes. As the organic loading increases with intensity of production, the bacteria that convert nitrite to nitrate operate less efficiently, resulting in increased nitrite levels. The accumulation of fine colloidal solids, dissolved organics and nitrite in RAS can impair biofilter function, and increase biochemical oxygen demand and stress levels in the cultured stock. The net effect of this residual organic waste is a less stable, less productive system.

Increasing the daily water exchange rate in an RAS will remove accumulated colloidal solids, refractory organics and nitrite, to the detriment of water budgets and the cost of heating or cooling the system. The alternative method of removal is to breakdown these organic wastes using an oxidizing agent, such as ozone. Ozone is also widely used to sterilise supply and effluent water for RAS to remove pathogens.

CONTACT US

Headquarters: No. 151, Canghu East Erli, Haicang District, Xiamen, China

Factories: Fujian, Guangdong, and Zhejiang provinces

Tel: 86-13606920716

Email: info@polextech.com

Email: felina@polextech.com