The oldest known photovoltaic power station in Europe, located in the canton of Ticino in southern Switzerland, this 10KW power generation system installed on the roof of the laboratory of the Swiss University of Applied Sciences and Arts, referred to as TISO‐10, has been running almost continuously since it was connected to the grid. 40 years.

The Swiss Federal Office of Energy (SFOE) invited two scientists Alessandro Virtuani, Mauro Caccivo and their research team from the Swiss Federal Institute of Technology in Lausanne to study the power station. The main measurement data includes a large amount of information between 1982 and 2017. Prof Mauro Caccivo said their team had to deal with countless documents and it took almost two years to sort out all the relevant information.

The construction cost of the TISO-10 power station was about $475,000 at the time (about $309,000 today), and the cost of all 288 modules in the project was about $37/W. The output power per module of this glass-backed panel 37W, the brand was Arco Solar, the largest module manufacturer at the time. It is understood that Arco Solar had an annual production capacity of 1MW at that time. It was first acquired by Germany’s Siemens and then acquired by Germany’s SolarWorld in 2007.

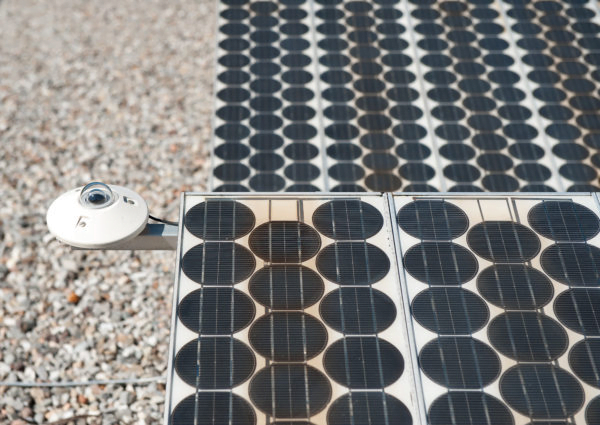

Although the electrical layout of the TISO-10 power plant system has undergone several changes, except for a few inverter replacements, all components have been used to the end, always exposed to the outdoors and sunlight, and have not undergone renovation or modification. , there are very few modules with junction boxes and bypass diodes replaced.

“The mechanical strength of these modules is amazing,” the two scientists stressed. However, the weight, size, and thickness of the cells do not reflect what might happen with the modules in use now or in recent years, because later Cracks may occur.

“But these components can tell us a lot about moisture penetration and yellowing. Each component is encapsulated with a layer of steel foil to prevent moisture from entering, and the steel foil is wrapped on both sides with the insulating material Tedlar.” They explain, Although the product’s structure is more like a glass/glass assembly than a traditional glass/backplane assembly, it is closer to what we define today as a dual-glass assembly.

This module has a conversion efficiency of 10%, an open-circuit voltage of 21.5V, a short-circuit current of 2.55A, a size of 1219mm × 305mm × 38mm, a single cell weight of 4.9KG, and is made of 35 single crystal cells with a diameter of 102mm. “Current cell technology is much more complex, including surface passivation techniques or multilayer structures. This complexity may make cells more fragile and subject to higher degradation rates,” the scientists added.

In total, the inverters were replaced five times, with Abacus controls supplying the original inverter equipment, which was replaced by Invertomatic ten years later, and the system design was revised with a longer package string connection. In the later stage, the SMA inverter was used, and the system design was restored to the original configuration.

The component performance of the TISO-10 plants varies significantly. The researchers divided the panels into three groups, with the best-performing modules showing little yellowing, while the other two groups showed moderate to high yellowing. “In the third group, the degree of yellowing was so intense that the components turned brown. The long-term electrical performance of the panels and the degree of aging were highly correlated with the encapsulation material,” the scientists said.

Chemical analysis in recent years has confirmed that the encapsulation materials of the three groups of panels are made of the same base polymer, polyvinyl butyral (PVB), but Arco Solar chose three encapsulation materials at that time.

Suppliers employ different additives in the polymer, resulting in different properties. “The details make or break! In this case, changing just one additive in the encapsulation material can affect the performance of the entire photovoltaic plant. This shows that the choice of encapsulation material is critical!” explained the researchers!

Because extracting polymers from components is a destructive means, the researchers were only able to perform chemical analysis on a limited number of components, but they ruled out other causes of degradation because the yellowing was only related to the encapsulation material.

About 21.5% of the modules showed a decay of -0.2% per year, which is also in line with the data promised by the manufacturers. And about 72.9% of the modules have -0.2%–0.7% attenuation per year. Scientists say most of the components performed well and met initial expectations. That is to say, at least 70% of the components in this power station meet the service life of 35 years.

The analysis also showed that 87.5% of the modules had some minor delamination and junction box issues, but these issues were fairly evenly distributed across the three panels. In addition, some components experienced cracking, backplane degradation, internal circuit corrosion, hot spots and smears.

The researchers emphasize that the first and most important lesson from PV plant installation and module research is that the bill of materials (BOM) is critical. The choice of material is just as critical today as it was forty years ago.

When asked whether the future of this older PV series is a maintenance improvement (albeit with lower power generation) or a direct replacement of the new system, the two scientists gave different opinions.

Mauro Caccivo said, “Economically, it is better to re-upgrade or simply replace the old plant with a completely new PV system. However, the European Commission has established a 40-year life cycle for solar modules, and it is reasonable to say that Photovoltaic products must be fully used until the end of their life cycle, or until 80% of their original performance is satisfied.” He added that through research on this ancient power station in Switzerland, it can be found that many modules have only -0.2% annual attenuation, the life cycle is much longer than 40 years.

Alessandro Virtuani believes that through proper operation and maintenance, the life cycle of photovoltaic systems can be extended. “If a photovoltaic system works well, it can operate for more than 40 years,” he explained. On the other hand, “some plants in Europe are currently commercialized with 30-year service life. If the systems and components work well, there is nothing stopping us from extending the operating time of the PV system.”

He also said that extending the life of a PV system beyond 30 years may also depend on the application of the PV system. For example, a photovoltaic water pump system does not need to be fully loaded for a long time, so its operating life may far exceed the owner’s expectations.

The results of the two research experts are published in two separate papers, “35 Years of Photovoltaics: Analysis, Safety and Performance Lessons of TISO‐10kW Solar Plants – Part I” and “35 Years of Photovoltaics: TISO‐10kW Analysis, Safety and Performance Lessons from Solar Power Plants – Part II”. Both papers were published in Progress in Photovoltaics.